For several months now people of Dhinkia in Jagashinghpur district of Orissa have been protesting against the project of Utkal Steel Industries Ltd. belonging to US$13 billion JSW group, owned by Sajjan Jindal .

On 14th January state atrocity against protesters became inhumane. They were subjected to brutal lathi charge. Elderly-children-women nobody was spared from the ruthless lathi charge. More than a hundred people were injured with broken limbs and fractured skulls. Many have been arrested and detained. The locals are scared and terrified.

It should be noted that, in order to divide the people of Dhinkia into three gram panchayets, the two new regions named Patana and Mahala were demarcated. Over the last few months, there has been a lot of tension regarding this division. The purpose of breaking up is to manipulate the gram Sabha decision in favour of the proposed steel factory. People of Dhinkia blocked the three entrances of their village with bamboo fences and went on a sit-in protest.

Jagatshinghapur is just two km away from the coastline of Bay of Bengal and is well known for its excellent quality betel leaf production. Most of the people there are Adivasis and make a living from growing and selling betel leaves. There is also some cashew nut cultivation. Being a coastal region there are people who earn their subsistence from fishing.

Sajjan Jindal’s proposed steel project in Jagatshinghpur is an integrated one. Along with the steel plant there will be a thermal power station and a cement factory. The total coast of the project is Rupees 65 thousand crores. The target for steel production is 13.2 million tons per annum and the target for power and cement generation is 900 MW and 10 MTPA respectively. A jetty will be constructed on the Jatadhar river adjacent to this area, for the convenience of transporting goods.

All this construction activity and industrial development is expected to damage the people, nature and environment of this locality. People of six to seven villages including Dhinkia will be affected. So, people have been forced to go on the path of protest-resistance.

This is the same site where the South Korean steel plant POSCO came up with its project after signing an MOU with the state government in 2005. About 3000 acres of fertile coastal land was given to POSCO, which had 5000 betel vines. Even at that time, the indigenous people of Dhinkia fought hard for their rights over water, land and forest. Finally, POSCO was forced to give up the project and hand over the land to the state government in 2016.

Despite the Forest Right Act of 2006, the indigenous peoples of this area have been deprived of their right to this land even after departure of POSCO. According to an estimate done in 2008, the POSCO project, if implemented, would have resulted in 3578 families losing their farm land and 718 families becoming homeless. However, although POSCO project could not be implemented, the environment was not completely protected from deforestation. The state government again handed over the land to Jindal group for a similar type of steel and associated industries. Note that the current project has not yet received environmental clearance from the Union Ministry.

India is the second largest producer of the raw materials in the steel industry around the world. China is in the first position for the same. India ranks third in the world as a consumer of the steel products while first and second positions are held by China and America respectively. Raw material for steel or crude iron is prepared in two ways. The product is called ‘pig iron’ in one process and in another process, the product is called ‘sponge iron’. In the financial year 2019-20 India produced 14% pig iron and 86% sponge iron. This huge amount of sponge iron is not produced anywhere else in the world.

Methods and pollution

Sponge Iron: This is a very ancient method of iron extraction from the ore. In this process iron ore or natural iron oxide is burnt in the presence of carbon so that the impurities inside it can be driven away. During this process as the solid waste–black ash, unburnt carbon, some burnt parts of reactor, floating silica and carbon particles are produced. The process also produces hydrogen, carbon monoxide and sulphur dioxide gas. In terms of pollution generation, it has been identified as a red category industry, better known as a ‘dirty industry’. The gas emitted from the chimney and other floating particles including silica are dispersed in the air far and wide. They slowly precipitate and make a red layer on the ground.

The Central Pollution Control Board recommended that the chimney height of the steel factory should be 75 metres. But due to the influence of private investors in this sector the height was finally reduced to 30 metres. The level of air pollution can be reduced to some extent by installing electrostatic precipitators or ESP .

Pig Iron: This method was invented in China in 11th century. In this process iron ore is melted in a blast furnace at a very high temperature and impurities are also removed. The molten waste is immediately cooled by pouring water on it and at the end it produces solid chips which can be used to make roads or to make dams in coastal areas. The element silica, present in it helps to grow algae in the water which increases oxygen level in the water. It is relatively cost effective though the process consumes lot of water. The amount of pollution is comparatively less in this method.

The growth of steel industry in India

According to the information received from the web page of the Indian Ministry of Steel, in 1991-92, there has been several changes in iron ore export and import policies. Summary of some important points are given below.

1.Steel industry was removed from the list of industries which were reserved as public sector and exempted from purview of compulsory licencing according to the Act of 1951

2.Iron and Steel industry has been included in the list of ‘high priority’ industries where foreign direct investment is automatically approved up to 51%, which has been recently increased to 100%.

3.Price and distribution were deregulated in 1992. Steel price is said to be fixed by the ‘market’.

4.Imports and exports have been made duty free

5.Upper limit in imports of iron and steel product are lifted and tariffs are drastically reduced.

6.Imports of seconds and defectives of steel are allowed only through three designated ports of Mumbai, Kolkata and Chennai, where the tariff has been reduced from 20% to 10% in 2006-7.

Although the list goes on and on, the reader, can see for sure when and how the blueprint for growth in the industry was created. Now we will see where iron ore is stored naturally rich and diverse soil of India.

Orissa, Jharkhand, Chhattisgarh and Karnataka are the major sources of iron ore. It is also found in some other states. In all cases, however the resources are naturally stored under the dense forests, inhabited by indigenous people who are exclusively dependent on those forests and adjoining lands for their livelihood.

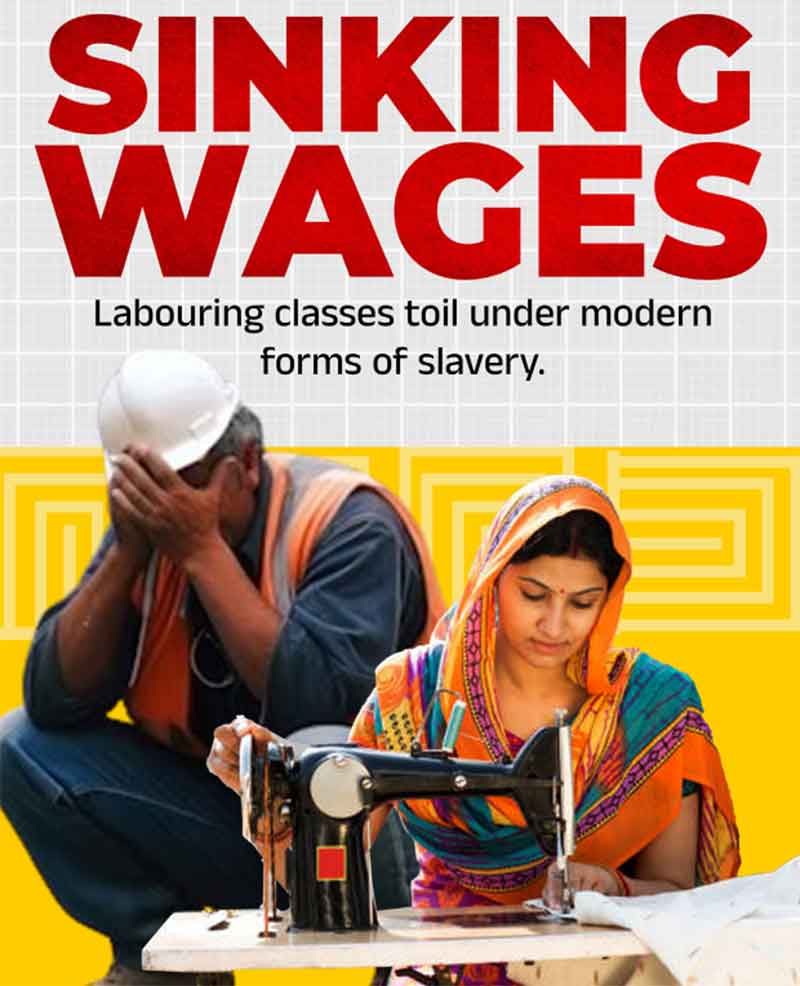

Although in this sector import-export business is run by big corporate house, who are connected to the international market, 60% of the sponge iron produced comes from small scale industries. Most of the time these small scale factories do not care about any rules and regulations. Though every state has made mandatory to install ESPs in the production system, most of them run their factories without it, in order to keep the production cost lower. Most of the time factories are unregistered, unauthorized. These companies do not contribute much to the local economy. Despite tall stories of employment and rehabilitation, the untrained indigenous people are only hired as contract workers at the factory. The poor unfortunate people are not even paid the declared minimum wages. People who work in this industry for long time suffer from silicosis, a lung related disease. That is why these companies often hire migrants to get the work done, so that they cannot pursue their demands for compensation.

At the time of land acquisition, in most cases, the reason for land acquisition is not stated clearly. In order to get the consent of the gram sabha, which is mandatory, in many cases companies get the work done by pressurising the village sarpanch in their favour. Muscle power, money and the political power act as the ultimate weapon. The monuments of success in these industries are built on deception, destitution of tribals, Dalits and people of the working class.

International Scenario

China, the world’s largest producer of iron and steel, has shut down two factories in Linyi and Chengde due to its air pollution. It also announced in 2016 that it would close several more coal and steel mills by 2020, where 15% workforce is engaged, due to excess production and declining demand. Many of these companies are zombie companies that means state are bound to give bailout in case they are in debt. So, in the name of pollution control China is trying to serve another purpose.

In America two-thirds of its iron and steel produced is made from recycled scrap, rather than from iron ore. In 2014, 81 million MT of iron and steel were produced from scrap mostly using electric arc furnaces. In 2019, in Ashtabula, Ohio one pig iron project has been launched in compliance with pollution protocols, which will begin operations this year.

In India due to the combination of the government’s policy of 100 percent FDI in this industry and world-wide despotism of finance capital our land-forest-water are being robbed using cheap labour of our country while polluting our air and soil.

Possible loss due to Jindal Project in brief

With the Himalayas in the North and the Deccan Plateau in the South, which is surrounded by sea on three sides, India is in the temperate zone. In all respects diversity is the main feature of this large tropical country. The southwest monsoon travels through Deccan towards North, is obstructed by the Himalayas and turns to Ganges Valley, and finally comes back to southern India via the northeast. During this journey it accumulates moisture, produced by forests and gives rainfall to the land. Agriculture in India depends on this rainfall. Across the country 46% of the Indian workforce is engaged in agriculture and produce a large portion of our annual food supply.

In 2007, scientists from St. Petersburg in Russia studied different forests around the world and discover it is the coastal forests which transfer the life-giving moisture to the landlocked forests in the interiors and cause rainfall. In this context, we should remember that the forest of Jagatshinghpur is a coastal forest. If the Jindal project is implemented, the forest will be cleared off and we might get a dessert in the middle area of India, in future. And hence a food crisis will erupt in India.

Carbon dioxide in the air is indispensable for trees to produce their food. This carbon is stored as wood in the body of trees through its life cycle. A research work published in 2004 shows that the older the tree, the more quickly it grows. That means older trees absorb more carbon dioxide from the air and reduce its temperature. Coastal trees reduce the temperature of the air above the sea. If the air above the sea reaches a temperature of more than 26.5° centigrade and the pressure becomes more than 200 ml. for two to three days, a cyclone is formed. So, if the coastal forest of Orissa is cleared off, the devastating cyclones like Ayla and Amphon will hit the eastern zone of India frequently.

Besides all these, forests are also important to maintain ecological balance. Here the plant-animal-microbes live in a chain where erosion and reproduction are balanced and the chain is maintained. But if the trees are cut down one after another and the forest is uprooted, there will be no more reproduction in this chain except decay. Eventually the chain of the ecosystem will be broken, which is called metabolic rift. Factory waste will gradually accumulate in the coast of Bay of Bengal which will affect the aquatic ecosystem and also create a rift there.

As production in the proposed steel plant will increase, so will the reproduction of capital, which will satisfy the greed of a handful of people. On the contrary, if the metabolic rift of the ecosystem continues to increase, it will gradually endanger the population of this country.

Resistance

People in the Sundargarh district of Orissa never get to see sunrise in the clear sky due to air pollution caused by the steel plant. An integrated steel plant project by Mahavir Hi-tech chemicals came up in Ratanpur near Sundarghar. It took five attempts at holding a gram Sabha meeting before a resolution could finally be passed on 28th February in 2005. Nearly 4000 people attended the meeting and amid police lathi charging said ‘no’ to the proposed plant unanimously. The people of Dhinkia also have a long history of giving stiff resistance against POSCO. Finally, they won against POSCO. Unfortunately today, they are once again forced to fight for their livelihood.

Pritilata Biswas is a political commentator